I’ve been meaning to build a new dining room table for our house since we moved in last year. A quick look at my /Now/ page showed that I bought the lumber for the base back in May. (It also shows I should probably update the /Now/ page.) It had been roughed out and stickered in the basement since then. Back in July, I made a trip out to Keim Lumber in Ohio and bought 5/4 cherry boards for the top. With Thanksgiving fast approaching, and plans to host at our house, I really need to buckle down and get this table done.

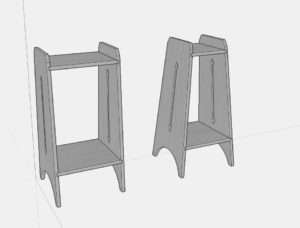

The plan for the table is based on a design published by Chris Schwarz* in Woodworking Magazine. The base of the table is made from yellow pine. The top will be made from cherry. After deciding that it had acclimated long enough, I started the process of milling it down on Friday, Sept 27, giving all of the boards a pass on the jointer until flat and then a light pass through the planer. They were then left to sit until Sunday the 29th. The legs, braces, and feet were then milled to final thickness, and the mortises were cut in the feet using a dado stack on the table saw. These boards were then glued up. The same procedure was done for the legs. The braces did not require any dados at this point.

As of yesterday, I had cut tenons on both legs and fit them to feet. I tried this by hand on the first leg with not horrendous, but unacceptable, results. The leg ended up snug but significantly twisted in the mortise. This was remedied by moving the operation to the table saw. I squared the tenon up using the dado stack and then glued on pieces to replace the previously cut away wood. This sat clamped overnight and I re-cut the tenon faces using the table saw again today.

In the meantime, the tenon was cut on the second leg via the table saw. I also took the opportunity to cut the bridle joint in the top of each leg using the band saw and a chisel, as well as cutting the mating piece in the braces using the table saw and dado stack.

By using the table saw, I got piston-fit joinery without too much hassle. At some point an upgrade of the table saw is on my list, if I think that the shop can stand losing the space to it. I’ve been working on a Ridgid R4513 jobsite saw for the past few years. I find that the accuracy of the saw, including blade tilt and height as well as fence accuracy just aren’t a great quality. That said, the saw folds down to save space, and in a 9 1/2′ x 18′ space, every inch that I can save helps.

Now on to shaping the feet and braces, and cutting the tenons on the stretcher.

* I have built a number of pieces that Schwarz has written about/researched/designed/built. I think this is a function of a few things. First, he is a prolific publisher. Seriously, the mere volume of written word on woodworking that he has put out there means that you are likely to find some piece interesting that you’d want to build or technique that you want to try. Second, the writing is amazingly accessible. He’s concise, but descriptive, easy to read, and amusing. Finally, the styles and techniques that he writes about are what grab my attention. Let’s face it, everyone has different tastes things, be it furniture, music, art, clothing, etc. In terms of furniture, I’ve now read, and own, three of his books (Campaign Furniture, The Anarchist’s Design Book, and Workbenches). I reference these books constantly in the shop and have found the styles of furniture that he gravitates toward to be the same style that interests me.